Tooling Services

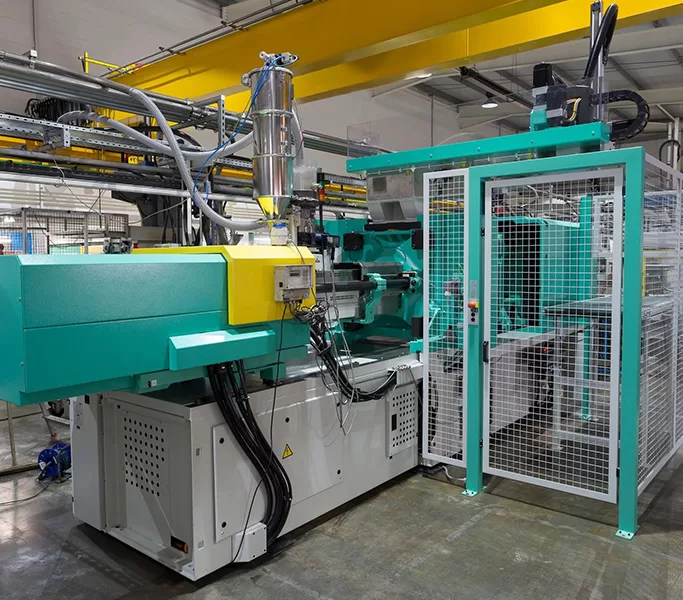

We understand manufacturing from the design phase, especially in injection molding. We design your files for manufacturability, minimizing common markings like ejector pin marks and gate marks. Additionally, we guide you on material choice, surface finish, timeline, and quality control based on product application.

Our Tooling Services

TWI-Industries is your trusted partner for top-notch injection molds.

Leveraging cutting-edge technology and a steadfast dedication to excellence, we skillfully convert raw materials into superior-quality products.

Mold Tooling

Plastic Injection Molding

Post Processing

Box Assembly & Packaging

Injection Molding Process

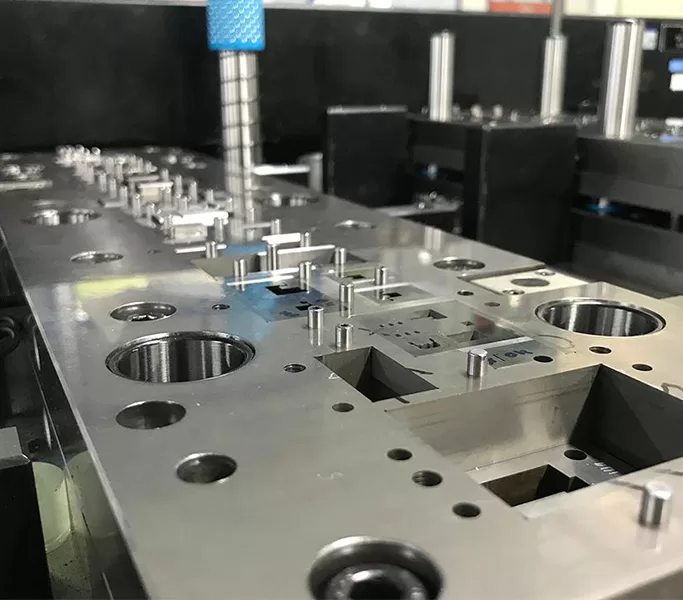

Mold Design and Tooling

The mold design and tooling phase is a crucial starting point. It involves creating a precise and well-engineered mold that will define the shape and features of the final product. Proper mold design considers factors such as part geometry, material selection, cooling systems, and gating methods.

Material Selection and Preparation

Selecting the appropriate material for injection molding is critical. Factors like material properties, durability, cost, and regulatory compliance must be considered. Once the material is chosen, it must be properly prepared for injection

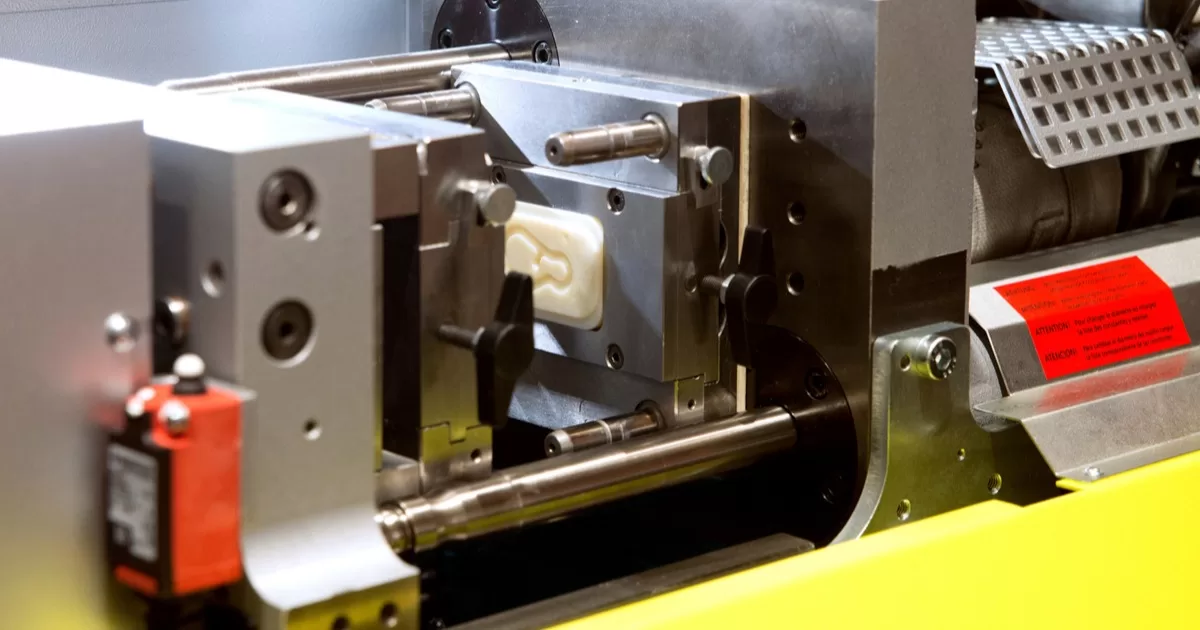

Injection and Cooling

In the actual injection phase, the molten plastic material is injected into the mold cavity. Maintaining precise control over variables such as injection pressure, temperature, and cycle time is vital to ensure the part's quality and consistency.

Let's Start A New Project Today

Passionate about innovation? Let's start a transformative new project and redefine what's possible.

Why Choose TWI-Industries for Injection Molding

Take advantage of our rapid manufacturing processes facilitated by state-of-the-art machinery to receive high-quality products, swiftly. We offer expert guidance in material selection, helping you find the perfect balance between durability, performance, and cost, all while meeting your specific needs with a focus on engineering and technical excellence.

High-Precision Tooling

We employ advanced tooling techniques, ensuring the production of components with tight tolerances and complex geometries, meeting the stringent demands of various industries including aerospace and medical sectors.

Material Science Expertise

Our team has deep expertise in material science, enabling us to guide clients in selecting the most appropriate materials for their projects, optimizing for performance, durability, and cost-effectiveness.

Accelerated Production Cycles

Leveraging the capabilities of high-speed CNC machines and automated systems, we ensure accelerated production cycles, facilitating rapid prototyping and mass production with a focus on maintaining dimensional accuracy and repeatability.

Customized Engineering Solutions

We offer engineering solutions tailored to your specific needs, utilizing simulation and molding analysis to predict and optimize the behavior of molded parts, ensuring optimal design and functionality.

Need Other Services?

At TWI-Industries, we don’t just focus on Injection molding, we’re your all-in-one solution. From cutting-edge product design and rapid prototyping to precision injection molding and circuit board manufacturing, we’ve got you covered. Explore our comprehensive suite of services to turn your ideas into reality.

Injection Molding

Learn more →

CNC Machining

Learn more →

Specialized Injection Molding

Learn more →

Metal Fabrication

Learn more →

Gallery of Our Work

Discover our impressive gallery of projects at Twi-industries. Dive into a visual journey showcasing our expertise in product design, prototyping, injection molding, and circuit board manufacturing.

Explore Related Resources

Crafting an Exclusive Manufacturing Route: Designing a Personalized Injection Mold

Custom Injection Mold Design: Discover the exclusive manufacturing route for crafting personalized injection molds. From requirement definition to design optimization and mold fabrication, learn how to create injection molds that meet specific needs.

7 Ways to Improve Moldability and Reduce Cost in Plastic Parts Manufacturing

Here are 7 key ways plastic parts makers can improve moldability and reduce total production costs including simulation, standardization, material selection, quality processes, and design for automation.

What is Injection Molding?

Injection molding is a forming process using molds. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the designed shape.