1、Introduction

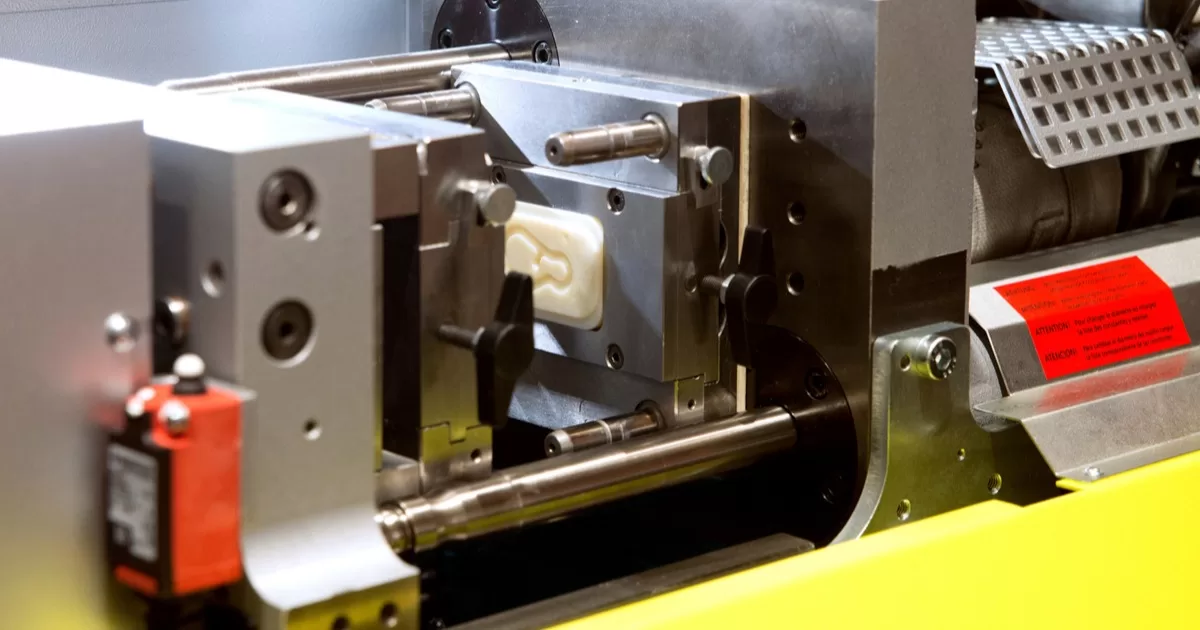

Injection molding enables manufacturers to deliver unique products with intricate shapes to meet the specific needs of end-users. This manufacturing process relies on custom injection molds to achieve this.

The complexity of the intended products often dictates the uniqueness of these custom molds. However, by using custom molds, it is possible to redefine manufacturing possibilities, unlocking precision, efficiency, and design flexibility.

In this article, we will explore the sophisticated world of custom injection molds and their transformative impact on the injection molding process.

We will also discuss the benefits of using this approach when off-the-shelf solutions are insufficient. Without further delay, let's begin.

2、What Are Custom Injection Molds?

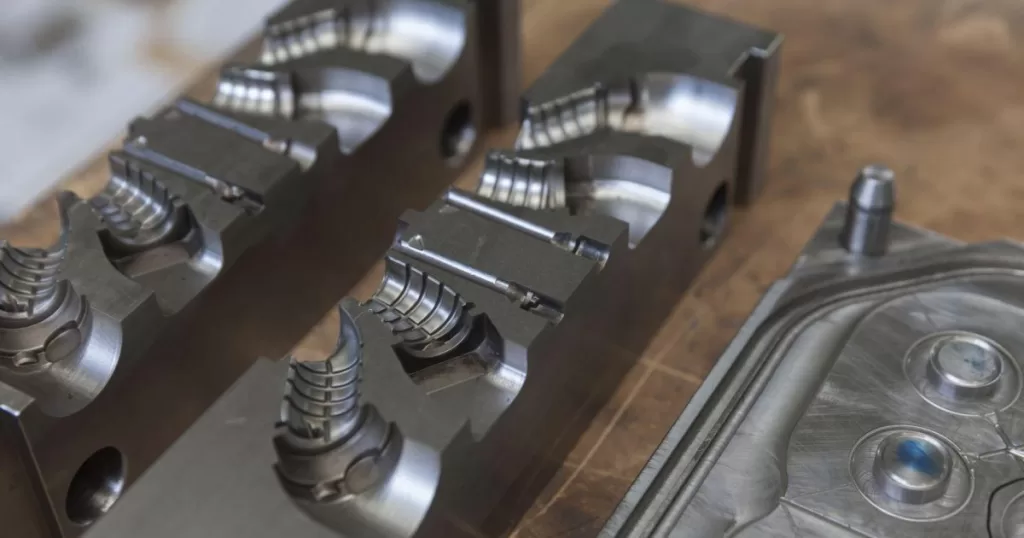

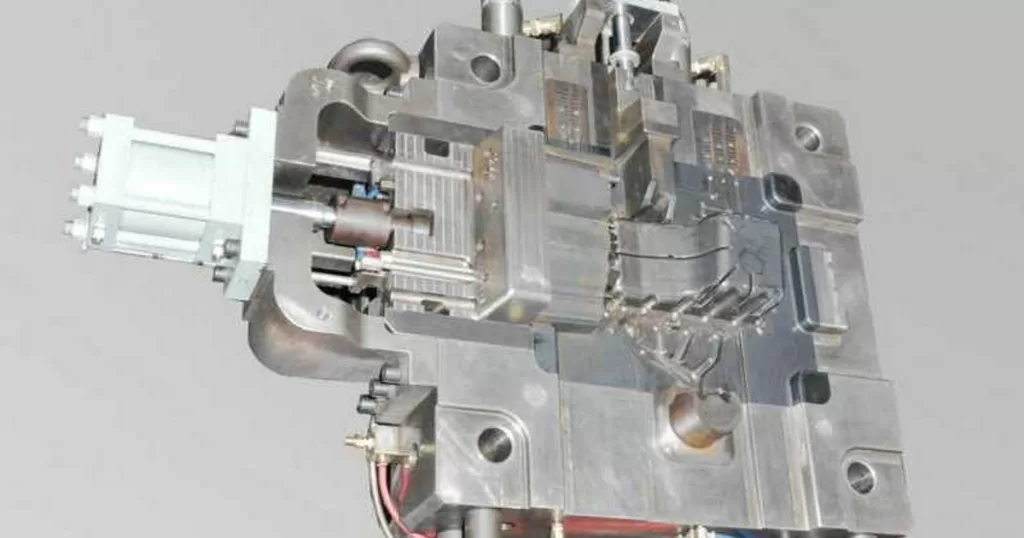

Injection molds are used to shape raw molten plastic into the desired shape. Custom injection molds are adapted tools crafted using high-quality CNC machining to bring uniquely designed products to life. The major differentiating factor between custom molds and conventional molds is the unique requirements needed for shaping a part, which can be handled effectively by a custom mold.

Standard molds offer some versatility, but they may not be specific enough for intricate designs or specialized materials. Custom molds, on the other hand, eliminate constraints and offer more flexibility for designers to explore new possibilities. It's like the difference between a ready-made suit and one that is meticulously tailored to fit.

Manufacturers often prefer custom molds for producing intricate parts that require meticulous details. Custom molds are crucial for injection molding because they help manufacturers overcome seemingly impossible feats.

The limitations encountered when using off-the-shelf molds, such as complex geometries, compliance with industry specifications, or the use of advanced materials, are reduced with custom molds. Custom molding is a necessity for injection molding due to these critical factors, rather than a luxury tool.

3、When to Consider Custom

Injection Molds Several factors can be responsible for using custom molds in an injection molding project. It is critical to know when to employ a custom injection mold in your project to operate and produce efficiently.

One common area where custom molds are used is in designing and manufacturing products with complex geometry. These products often require ingenuity and the use of custom molds.

Custom molds are particularly useful in the manufacture of specialized components that are not mass-produced but are used to achieve specific one-time objectives.

These are just two common scenarios, but they can vary across different industries, highlighting the uniqueness of using custom molds in injection molding.

Despite this, the benefits of custom molds in meeting specific manufacturing needs often outweigh those of conventional molds. This is because they offer greater precision and quality for special designs.

Another advantage of using a custom mold is its long-term cost-effectiveness compared to off-the-shelf molds. Custom molds eliminate the expensive iterations of mold parts that are often required with traditional molds. Furthermore, they reduce material and time wastage while increasing efficiency, resulting in significant cost savings over time.

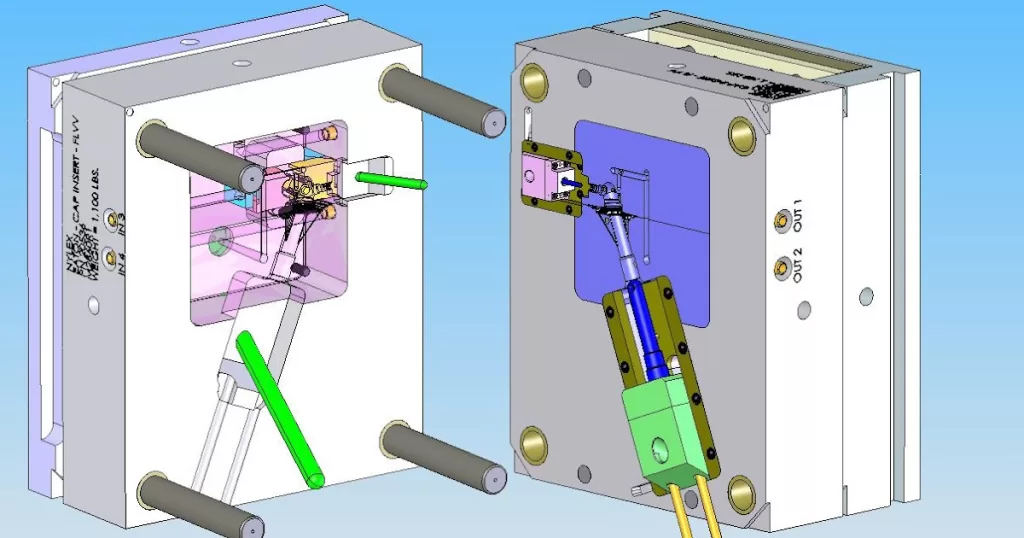

4、Designing Custom Injection Molds

No manufacturing work is complete without a detailed plan that itemizes the constituent elements and their specifications, including dimensions, size, and shape. Therefore, custom mold design is crucial to achieving molds that meet unique project requirements at a higher level of quality. The durability, functionality, and performance of the product are directly related to the meticulousness put into the mold design process.

Design experts and mold engineers have a significant influence on the success of manufacturing an effective custom mold. Their collaboration can make or mar the outcome of the bespoke injection mold. Therefore, it is essential for mold designers and engineers to establish an effective communication channel to facilitate their collaboration. This partnership guarantees a seamless alignment between the project's requirements and mold design, promoting efficiency and innovation in high-quality mold manufacturing.

However, certain factors must be carefully considered when designing a custom injection mold. When designing a product for injection molding, it is important to consider factors such as mold material compatibility and the ability to scale production volume in the future. These critical evaluations can significantly impact the long-term performance and adaptability of the product, as well as the mold production process.

5、Optimal Material Choice for Custom Molds: Paving the Way to Impeccable Manufacturing

The process of selecting materials for custom mold production can be likened to an artist selecting the perfect color palette. It plays a crucial role in determining the level of precision achievable in transforming concepts into reality. Therefore, choosing the right material for custom mold manufacturing is vital for ensuring the success and quality of the final product. Additionally, factors such as durability, heat resistance, and the specific requirements of the intended application must be carefully considered to meet design specifications and industry standards.

Notably, each application has unique requirements, necessitating different criteria for material selection, especially in the case of custom mold projects. It is crucial to tailor the material appropriately to fulfill the intended application, whether it involves high-temperature molding or intricate detailing.

Similarly, striking a balance between the cost of mold materials and the desired performance is a critical aspect that requires careful evaluation. Since custom molds are tailor-made, the material costs may exceed the average. Nonetheless, as mold designers, it is essential to achieve a delicate equilibrium between cost and performance, ensuring durability and precision are not compromised.

6、Prototyping and Testing: Paving the Path to Perfection

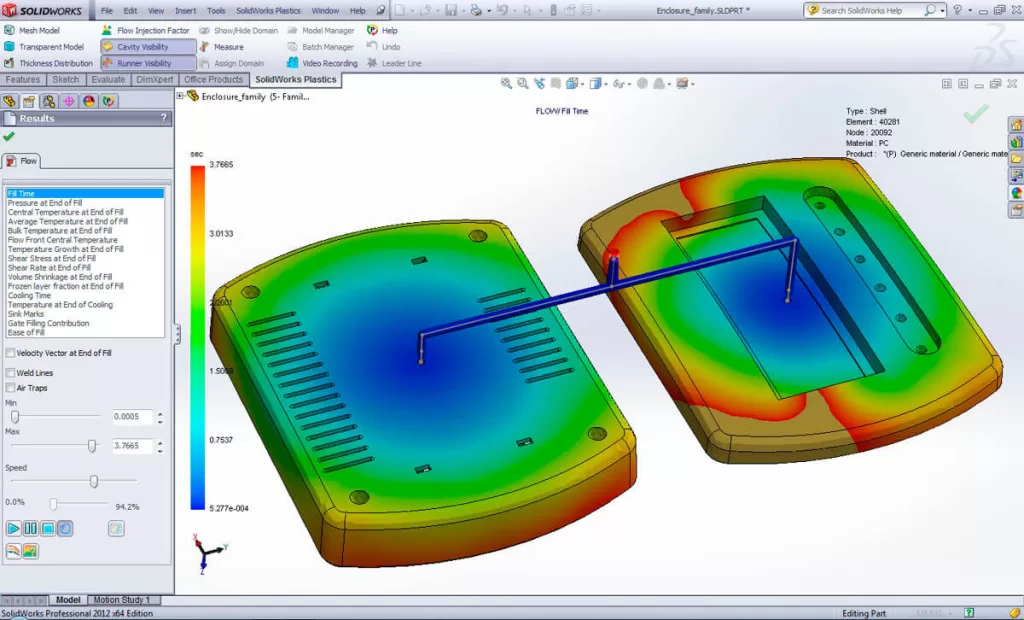

In the realm of top-notch mold manufacturing, the journey towards creating flawless custom molds often commences with the development of a minimum viable product through prototyping techniques, such as 3D printing technology. This crucial stage allows for continuous adjustments and refinements before proceeding with the final production of custom molds on a larger scale.

However, the ability to undertake thorough testing and iterations serves as a key indicator of progress towards achieving success with custom molds. The test results obtained during this phase serve as the foundation for fine-tuning the molds, focusing on critical aspects that ensure the production of impeccable products. Therefore, a robust testing phase is essential to deliver high-performance molds, addressing factors like consistent material flow and validating the structural integrity of the mold.

Simultaneously, the quality and performance standards established during the design of custom molds are of utmost importance in the mold prototyping process. Meeting these non-negotiable criteria is paramount, as they form the backbone of any manufacturing endeavor. Every aspect, from dimensional accuracy to optimization of cycle time, undergoes meticulous scrutiny to ensure that the custom mold aligns with the highest standards of quality and performance.

7、Advantages of Custom Injection Molds: Unlocking an Array of Benefits

Custom injection molds offer a plethora of advantages for both manufacturers and end-users, particularly in their ability to produce complex yet highly functional products. However, realizing these benefits relies heavily on the ingenuity of the mold designer in crafting the specifications for these custom molds. Let's delve into the major advantages of custom molds below.

- Unparalleled Precision and Quality Control: Custom-made injection molds surpass the precision and quality achieved with conventional molds, and for good reason. These molds involve intricate details, and any deviations from the intended specifications can have disastrous consequences for the product's functionality.

- Waste Reduction and Cost-effectiveness: The cost-effectiveness and waste reduction associated with custom molds stem from their high precision. This precision enhances process efficiency, minimizing material wastage and reducing production costs. This economic advantage is a key reason why custom molds are favored by many manufacturers.

- Enhanced Design Flexibility: Custom molds empower designers to unleash their creativity and develop molding solutions that best meet the unique challenges posed by a specific product. The design flexibility of custom molds enables them to adapt to diverse production requirements, resulting in highly tailored and optimized products.

- Shorter Lead Times and Faster Time-to-Market: Another significant advantage stemming from the precision offered by bespoke injection molding is the considerable reduction in production time. This enables manufacturers to bring their products to market swiftly compared to other types of molds, gaining a competitive edge.

In summary, tailor-made injection molds offer a plethora of benefits that make them highly sought-after by manufacturers aiming for flawless plastic production. Their ability to deliver unmatched precision, cost-effectiveness, design flexibility, and faster time-to-market has solidified their position as a preferred choice for realizing unique and exceptional products.

8、Challenges and Considerations

While manufacturing methods have many advantages, they also present challenges.

Custom-made injection molds, in particular, are not without their fair share of trials. However, identifying these challenges is the first step in dealing with them.

For instance, a major challenge of custom molds is achieving the intricate complexities that often accompany them. At times, the production of these complexities may necessitate the use of advanced tools and sensors to monitor them with the utmost precision.

Another challenge is selecting appropriate materials that meet the requirements for mold production. With numerous material options and their varying properties, it may be difficult to find a single material that meets all demands. Designers often use these challenges as inspiration to create unique material combinations.

However, these challenges should not hinder the execution of quality control and assurance responsibilities, which are crucial for producing a reliable custom mold. Implementing an efficient quality management system at the start of the project is considered a best practice in the high-quality mold manufacturing industry.

Overall, it is important to strike a balance between achieving the desired level of quality for the custom mold and staying within the allocated manufacturing budget. Customizations should not result in exceeding the production cost, and budget constraints should not lead to a substandard mold.

9、Finding the Right Custom Mold Manufacturer

In addition to selecting the most appropriate materials for a tailor-made injection mold, choosing a suitable mold manufacturer is a crucial decision that requires careful planning.

This process begins with researching custom mold manufacturers, typically using online resources. Utilising search engines such as Google can simplify the search. Experienced colleagues can provide valuable guidance when embarking on such projects.

However, when searching for a reliable custom mold manufacturer, it is important to consider factors such as experience, technical expertise, and a proven track record of delivering high-quality molds.

Emphasising these qualities can assist businesses in selecting a mould manufacturer that aligns with their specific needs.

Additionally, maintaining effective and open communication with the bespoke mould manufacturer can facilitate a smooth transaction, resulting in a spectacular mould masterpiece. This fosters a spirit of collaboration rather than the strife that often characterises transactions where miscommunication is prevalent.

Effective communication ensures that both parties are aligned on project expectations, leading to the creation of custom moulds that precisely match the client's requirements.

10、Real-World Applications: Unleashing the Power of Custom Injection Molds

The realm of injection molding boasts a multitude of real-world applications where custom-made molds have revolutionized the production of remarkable products, greatly impacting the lives of countless end-users.

- Automobile Industry: The automotive sector relies heavily on custom-made injection molds to manufacture various unique parts and components that are vital to the functioning of vehicles. From intricate engine elements to specialized interior and exterior components, custom molds play a pivotal role in creating the complex and integrated systems found in automobiles.

- Consumer Electronics: Custom molds play a crucial role in the production of components for consumer electronics. From microwave ovens to smartphones and personal computers, these everyday devices owe their existence to the versatility of custom molds. The ability to create components of different shapes and sizes allows for the development of innovative and technologically advanced consumer electronics.

- Household Items: Injection molds have demonstrated their transformative capabilities by converting simple shapes into complex components that form essential household items. From kitchen appliances to furniture accessories, custom injection molds enable the efficient production of high-quality products that enhance everyday life.

- Medical Devices: The medical industry heavily relies on custom injection molds to manufacture a wide range of critical equipment and devices. From intricate surgical instruments to complex medical implants, custom molds ensure precision, reliability, and safety in the production of medical devices that improve patient care and save lives.

These examples merely scratch the surface of the limitless possibilities offered by custom injection molds. They have not only increased efficiency and streamlined production processes but have also facilitated the development of innovative designs and superior-quality products across various industries. The transformative power of custom injection molds continues to shape our world, enhancing functionality and driving technological advancements.

11、Conclusion: Harnessing the Power of Custom Injection Molds

In summary, custom injection molds are indispensable tools that enable manufacturers to bring intricate and complex products to life, surpassing the limitations of traditional manufacturing methods. Their significance in the world of injection molding cannot be overstated, given the multitude of benefits they offer.

Custom molds provide increased efficiency, leading to cost-effective production and reduced material wastage. They empower manufacturers to achieve higher levels of precision and quality, ensuring the creation of flawless products. However, it is crucial for injection molding manufacturers to partner with the right custom mold provider, one with technical expertise, experience, and a proven track record. Such a partner instills confidence in their ability to deliver high-quality custom molds that cater to unique requirements.

Quality and precision are paramount in the realm of custom injection molds, and finding the right partner who can consistently deliver on these aspects is invaluable to the success of any project. By harnessing the power of custom injection molds, manufacturers can unlock new possibilities, drive innovation, and elevate their production capabilities to new heights.