Crafting an Exclusive Manufacturing Route: Designing a Personalized Injection Mold

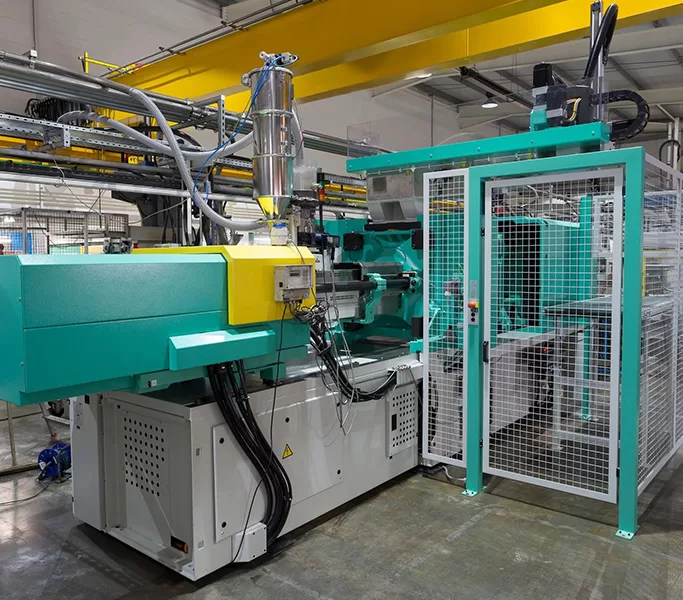

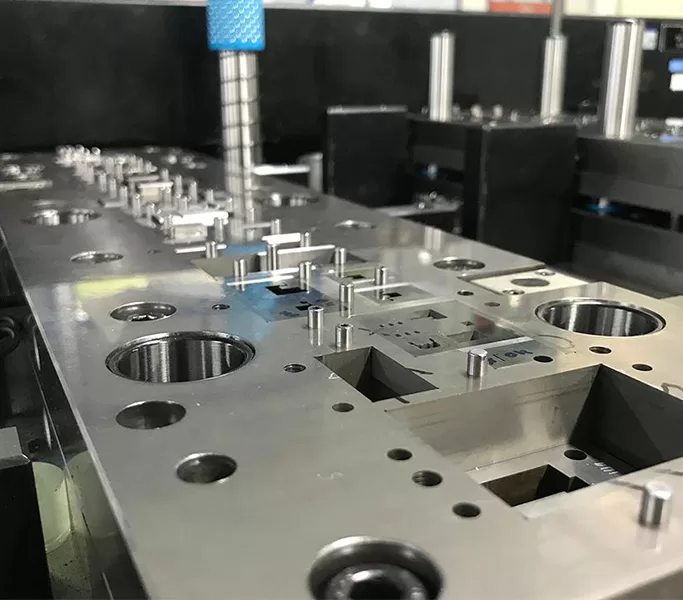

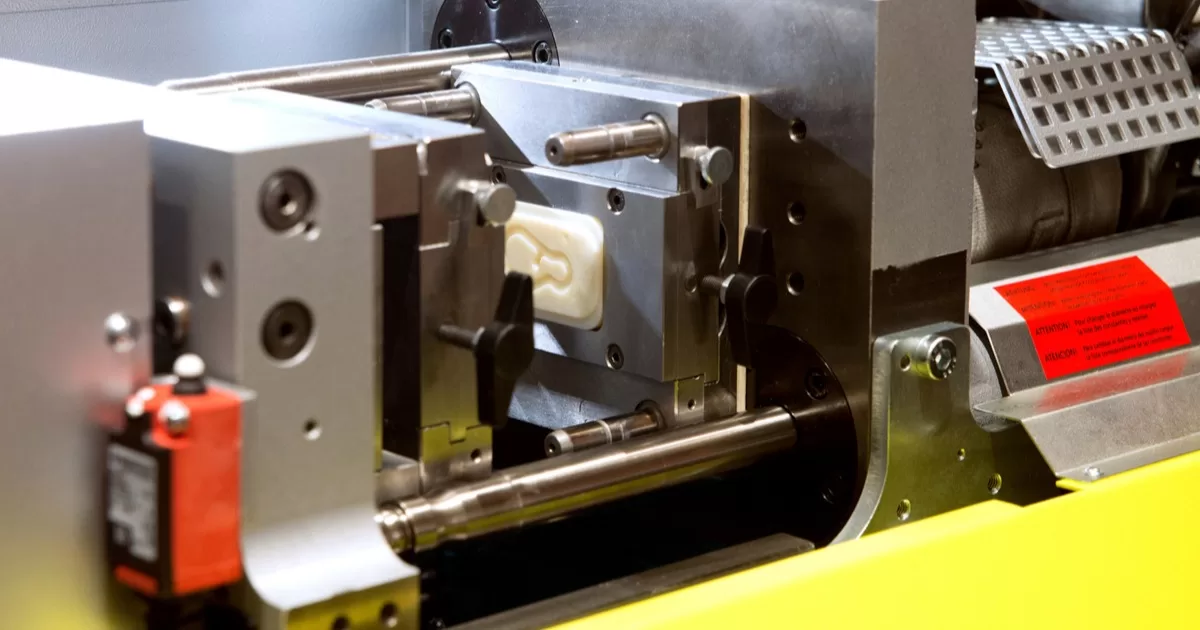

Custom Injection Mold Design: Discover the exclusive manufacturing route for crafting personalized injection molds. From requirement definition to design optimization and mold fabrication, learn how to create injection molds that meet specific needs.